Plant safety is a high priority across industries. Hazardous environments and complex systems where humans work alongside machines require high safety standards to protect both people and processes.

Workplace safeguards can be built-in using protective devices. Below, we outline the usage of interlock and solenoid switches, enabling switches, safety mats, light curtains, safety relays and e-stop switches in protecting personnel.

Where Safety Devices are Needed

These devices protect machine operators on automated lines, minimize the risks for personnel in material handling, packaging and warehousing and allow for tasks such as loading/unloading, machine set-up, cleaning and maintenance to be carried out safely. Protective systems integrate with overall control systems, enabling humans and machines to work together safely.

Interlock Switches

Also known as disconnect switches, interlock safety switches prevent unsafe situations by detecting the position of a door or guard and controlling the process accordingly, usually by switching off the flow of current to a machine when a guard is removed. Guard lock and door switches prevent access to hazardous areas until a safe state is reached. Keyed interlock switches require a key to activate or deactivate. The key will be trapped while a process is in an unsafe state. For example, an operator may be required to isolate power before releasing the key required to open a gate to access a machine.

Solenoid switches reduce the risk of operator injury where a system takes time to become safe after a stop request, for example high-inertia rotating machines or high-pressure valves. A solenoid switch can be connected to a control circuit to set a time delay or require parts to stop moving before the switch opens.

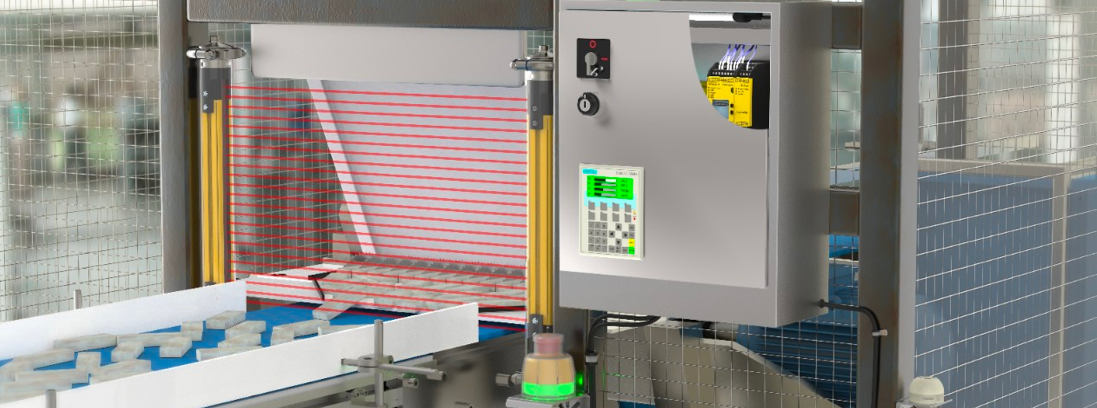

Light Curtains & Safety Scanners

Safety light curtains detect the movement of objects and people within potentially dangerous areas using a set of beams of light across a space. Light curtains protect personnel by stopping machinery when someone stepping or reaching into an area interrupts a light beam. The absence of a door or guard reduces the time required for loading, inspection, or adjustment operations and allows free access to a machine, panel or process whilst ensuring safety.

Safety laser scanners operate on the same principle as a light curtain, using beams of light to detect people or objects and send a signal to stop machine movement, but offer a more flexible field of protection. Scanners can be attached to a moving arm or vehicle and offer 360 degree detection of people or objectives within a range of several meters.

Safety Mats

Pressure-sensitive mats are used in front of or around potentially dangerous machines or robots. The mat safeguards against injury by detecting pressure when an operator steps onto the mat and stopping the machine. Safety mats allow unimpeded access for loading, unloading and adjustment. Many mats also provide anti-slip protection.

Two-Hand Control Stations & Footswitches

Two-hand control stations protect machine operators. The control station requires the operator to have both hands on the controls, keeping hands away from a potential risk such as a press or die. Removing a hand from the controls will halt the operation.

Footswitches allow hands-free operation in applications like table routers, packaging equipment, conveyors and presses. Footswitches are usually protected with a shield to prevent unintentional operation. Where footswitches are used, additional safety devices, such as a two-hand control station or machine guard, should be in place to prevent an operator accidentally placing hands in the dangerous area.

Enabling Switches

Enabling switches permit safe access to hazardous areas for non-routine work such as set-up or servicing. The manually-operated switch has three positions as standard – off-on-off – with machine operation only permitted when the operator lightly presses the switch. If the switch is released or depressed further, the machine is disabled. This ensures operator safety by halting movement when an operator clenches or drops the switch as an instinctive reaction to a dangerous situation.

E-Stop Switches

Manually operated emergency stop switches halt machine operation when pulled or pressed by an operator, allowing operators to stop a process when they see unexpected risks to people or production. E-stops complement other safety measures and are required in many workplaces to comply with safety standards.

Push-button e-stops positioned in the area of operation stop a process when pressed. The button is either pulled or twisted to reset the switch.

Cord pull e-stops can be used to cover long areas such as conveyors. The cord can be pulled at any point on the line to stop movement when a risk is observed.

Key-release e-stops require a key to release the switch once activated. This provides additional protection against accidental or premature release.

Safety Relays

Safety relays are an integral part of an overall control system, monitoring & processing signals from devices like light curtains, pressure mats, e-stops and interlock switches. Safety relays can receive input from several devices on the shop floor and use the information received to control an actuator for overall plant safety. A safety-rated PLC may be a better choice than a safety relay in more complex environments: where inputs are numerous (more than 3 or 4 inputs) or complex, where sensing devices are a significant distance from the control system or where programming flexibility is required.