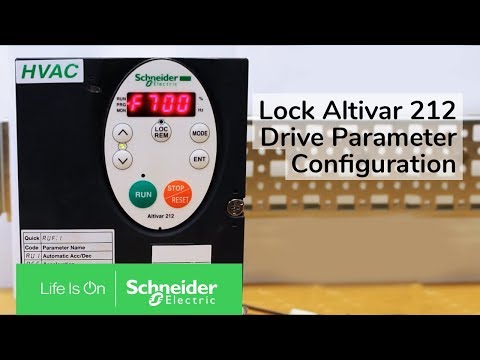

Schneider Electric ATV212HU75N4

AC Variable Frequency Drive, 380-480VAC, 3P, 10HP

Mfr. Part #: ATV212HU75N4 /

RS Stock #: 70008299

Better World

Price

Qty.

Standard Price

1

$1,216.06

Additional Inventory

Manufacturer Lead Time:

1 week

Estimated manufacturer lead time is for quantities greater than shown above.

Product Specifications

Product Attribute

Attribute Value

Search

Ambient Temperature

-10 to 40 °C

Better World Product

Yes

Better World Verification

Green Premium

Communication

Modbus RJ45

Current Rating

16 A

Driver Type

Variable Speed

For Use With

3-Phase Motors

Frequency

0.5 to 200 Hz

Horsepower Rating

10 HP

Motor Power Rating

7.5 kW

Mounting Type

Panel Mount

Output Frequency

0.5 to 200 Hz

Overall Depth

6.693” (170mm) in

Overall Dimensions

6.693 x 9.134 x 7.087” (170 x 232 x 180mm)

Overall Length

9.134” (232mm) in

Overall Width

7.087” (180mm) in

Phase

3 Phase

Power Rating

7.5 kW

Primary Type

AC Drive

Special Features

Pump/Fan Functions

Standards

C-Tick, CE, CSA, EN 55011, EN 61800-3, EN 61800-5-1, EN/IEC 60529, EN/IEC 61800-5-1, IEC 61000-4-2, IEC 61000-4-3, IEC 61000-4-4, IEC 61000-4-5, IEC 61000-4-6, IEC 61800-3, IEC 61800-5-1, NOM 117, UL

Supply Voltage

480 VAC

Type

Variable Frequency

UPC Code

785901944775

Overview

Pump/Fan Functions

Schneider Electric Altivar 212 Series - Dedicated HVAC Drives for 0.75 to 75 kW Motors:

The Altivar 212 is a variable speed drive for 3-phase asynchronous motors from 0.75 kW to 75 kW. It is specifically intended for the most commonly encountered fluid management applications in tertiary sector buildings (HVAC): heating, ventilation, air conditioning and pumping. Due to its eco-energy based design, energy savings of up to 70% can be achieved compared to a traditional control system.

Features:

Instant viewing of the energy consumption

Detection of failures for quick intervention: belt breakage, pump running dry, phase failure, supply fault, etc.

Preventative maintenance for reducing costs and optimizing the equipment: fault alert, operating time, etc.

Connection to building supervision network using ebmedded protocol

Dedicated "Building" series functions (fire mode, register monitoring, mechanical protection function, etc.

Communication bus most commonly used on the market integrated: Modbus, METASYS N2®, APOGEE FLN P1® and BACnet®. Optional: LonWorks

Complies to international standards and certifications: UL, CSA, C-Tick and NOM

Antiharmonic technology enables a THDI < 30% to be achieved

Speed range: 1:50

Transient overtorque: 110% - 60 s.

Integrated EMC filters, categories C1 to C3 depending on model

Altivar 212 covers motor powers between 0.75 kW and 75 kW on the following supplies:

- 200...240V 3-phase, from 0.75 kW to 30 kW, IP 21

- 380...480V 3-phase, from 0.75 kW to 75 kW, IP 21

- 380...480V 3-phase, from 0.75 kW to 75 kW, UL Type 12/IP 55

Applications:

Less noise pollution (airdraulic noise, motor noise, etc.)

Detection of transmission component breakage

Smoke extraction: forced start with fault inhibition

Automatic restart

Allows register management

Optimize control in fluid processing

Use of PID controller (temperature, flow rate, pressure, etc.)

Adjustable flow rates for better energy management

Suppression of mechanical resonance

Detection of underload/overload, pump running dry

Multi-motor configuration

Limitation of operating time at low speed

Sleep/Wake function

Pressure surge suppression for prolonging the life of the installation

Schneider Electric Altivar 212 Series - Dedicated HVAC Drives for 0.75 to 75 kW Motors:

The Altivar 212 is a variable speed drive for 3-phase asynchronous motors from 0.75 kW to 75 kW. It is specifically intended for the most commonly encountered fluid management applications in tertiary sector buildings (HVAC): heating, ventilation, air conditioning and pumping. Due to its eco-energy based design, energy savings of up to 70% can be achieved compared to a traditional control system.

Features:

- 200...240V 3-phase, from 0.75 kW to 30 kW, IP 21

- 380...480V 3-phase, from 0.75 kW to 75 kW, IP 21

- 380...480V 3-phase, from 0.75 kW to 75 kW, UL Type 12/IP 55

Applications:

Bulk pricing available

Bulk pricing available